Knitting wool defect refers to long-fiber raw materials, due to the equipment, technology, raw materials, commissioning, operation and other reasons, resulting in raw fiber breakage during weaving section, fracture in the fabric fibers tilt surface, forming fluff defects. Refers to a narrow vertical hair pin hair pin, hair pin also includes a broad horizontal and other irregular fuzzy.

When weaving long fiber materials and single fiber breaking strength is relatively low raw wool knitting defects, such as polyester yarn, nylon yarn, silk, rayon and other prone. Hair pin phenomenon occurs when the production of polyester light cotton cloth, mainly because of poor elasticity FDY bright polyester filament fibers, some fibers break easily, resulting in fuzzy.

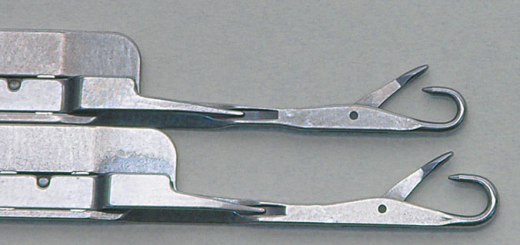

To prevent hair pins, needles should be selected first, and too new or too old knitting needles are prone to hair-pin. New needle needle tongue is not flexible, and the hook part is not smooth enough, will fibers from the yarn hooking up; excessive aging needles surface after prolonged use and wear will occur, may also occur hair pin. So should choose seven gently used needles is ideal. Second, we must consider the condition of the cylinder and dial, to ensure that no serious wear and tear.

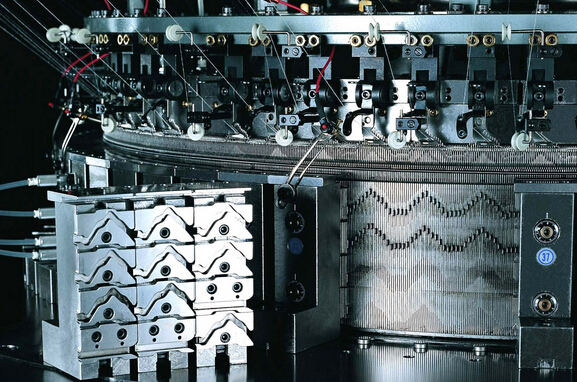

In commissioning, the first triangle to adjust to the position, if it is with tuck fabric, try to synchronize into a circle; tuck if it is not organized, the needle plate, syringes triangle to just stagger, that just completed a syringe needle pressure needle, dial needles immediately into a circle. Second, we must adjust the position of the yarn mouth, the upper limit of the principle of not leak yarn, yarn feed does not clip to latch closed position; limit is not caught by the yarn scissors mouth to the principle; inward to ensure that the yarn is not yarn and needles clip to mouth; not leak out to the principle of the needle. Also check the craft and fabric density structure is reasonable, the density is too high can also cause hair pin. In addition, the lack of precision equipment; 6 “degree” equipment (syringes roundness, flatness with the roundness, the needle plate roundness, flatness, syringe and needle plate and the same roughness) is not fine; and because machines are often different varieties of organizational change, resulting in the butt, inconsistent wear needles, knitting wool are likely to cause defects.

In addition, the hair-pin and double circular knitting machine also outside diameter of the needle plate design dimensions of a relationship, the outside diameter is too large, prone to hair-pin weaving; while the outside diameter is too small to produce the cloth is not crisp.

Threading clip should always finishing, porcelain eyes will be no need, but also to check the yarn, the yarn through the hole, and from the creel to feed the entire yarn path between yarn mouth is smooth, if there are glitches can also cause hair pin.

Most wool knitting defects can be found before the dyeing process, the specific method is: in low light areas, very stretched canvas, canvas side illumination (light and fabric surface was 10 with light (flashlight required) ~ 15 ° angle), broken hair pin will appear above the fines reflect light in bright light, very obvious. Require the operator at the time of each piece of fabric under the machine, should carefully review the positive and negative; and in off the bottom yarn, bad needles, holes, missing needles and other defects cloth to cloth roll above, the upper end should immediately inspect defects hairless needle. In addition to the rough cut of about 3 m were finishing, so that you can easily find wool knitting defects. Weaving process, there is a way to discover the hair pin: If a needle groove has more fly, then there was the possibility to have a hair-pin; mouth if a yarn fly back or lower end have more accumulation so there may have hair weft needle.

If the fabric surface appears hair pin can also be first with a time machine woven fabrics of other raw materials, and then change back after a formal raw materials, sometimes this method also resolves hair pin problem. If wool knitting faults, but before the machine is to use cotton and other raw materials, you need to clean the machine, and then replace all the needles. In order to avoid the phenomenon of hair pin, should try to use a single fiber breaking strength is good, or better monofilament elastic material, some material may be appropriate to increase the number of network points will also be improved hair-pin.