Denim fabrics are courser than woven fabrics. In general, courser yarn is used as raw materials for denim fabrics. Finishing is used to add some properties to denim fabrics having been dyed and woven.

The followings are the processes of finishing for denim fabrics

1.Grey fabric roll at feeding scray

2.Brushing

3.J-Box

4.Gas singeing (2-burner)

5.Brushing

6.Chemical box

7.Squeezing padded

8.Skew roller

9.Dryer-1 (10 cylinders)

10.Rubber belt

11.Stenter (except stretch denim)

12.Palmer

13.Cooling roller and folder

Various types of machines are used for performing finishing.

Mahine-1: The machine whose brand name is Sperotto Rimer is used in the beginning of finishing. The machine is made in Italy.

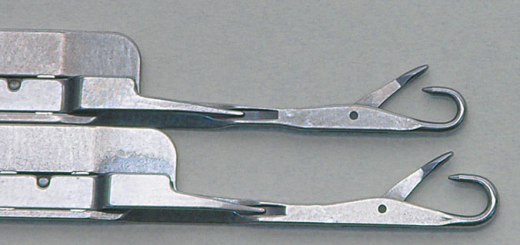

Singeing unit: Osthoff-Senge singeing machine which is manufactured in Germany is used for singeing unit removing hairy fiber.

Padder pressure (air pressure): Padder pressure maintained following parameters:

7000 kg (for stretch denim)

2000 kg (except stretch denim)

Machine-2: Machine-2 is used for:

Sanforizing unit manufacturer- MONFORTS (Germany)

Up to the dryer unit manufacturer- KTM (USA)

General output speed- 50 m/min.Used chemical- Softener (Belsoft). Mixing tank contains 1200 Liter of softener solution which requires 20 kg softener for 1200 Liter.

The sequence of processes and types of machines are different because of the requirements for products.