Needles and triangle are involved knitting processes. For this, quality of needles, craft points of knitting and boundary dimension have closed relationship with the quality of fabrics surface.

Relationships between needles and knitting craft

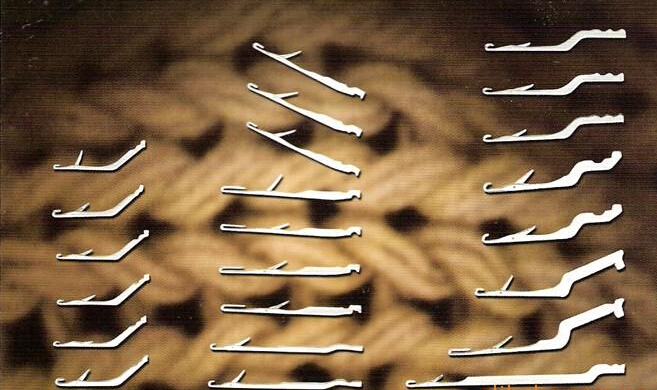

Boundary dimension of needles includes lengths of latch, sizes of syringe needles, types of pinhook and width of needles.

1.Lengths of latch

Generally, lengths of latch refer to the distance from needle to pin of latch when the latch is on and sticks on needle bar. Vo 141 needles in common use in market include 7mm, 8mm and 9mm. Vo 123 needles are classified into 6mm and 8mm two types. Different lengths should be equipped with different streamlining of triangle. The longer length of latch is, the higher needle point of triangle is. The distance from head of needles to tip of the latch is the smallest stroke in latch knitting. Triangle curve should have larger stroke than length of latch. Under the circumstance that loops do not change, the longer length of latch is, the more precipitous triangle curve is and the larger fluctuating value is when needles knitting yarns. The fluctuating value has great influence on surface of gasket. Due to low fluctuating value, it is advantageous for improving the stability of spandex. However, the shorter latch is, it is disadvantageous for widening horizontal angle of laid-in yarn. So, when short latch is used for tucking spandex or cotton silk, the stability is quite poor, which is bad for demultiplexing of machines. So, short latch is widely applied in circular knitting machine demultiplexing.

Size of needles

Sizes of needles mean the lateral dimension of pinhook. The larger pinhook is, the more easily yarns be hooked during yarns laying, which can reduce drop stitch and hand pick. In general, sizes of needles range from 0.8mm to 1.6mm. When processing yarns having high thickness, pins should be used. What’s more, needles have impact on knocking over. If the pins are overlarge, loops are expanded during knocking over, increasing tension of loops and resulting in soft sides when knitting dense fabrics. Similarly, if pins are too small, defective cloth is easily produced when knitting fabrics having poor quality and short yarns. However, small pin can knit fabrics having clear lines and quality.

Moreover, in market, needles used by double faced interlock machine have 3 categories. The first one is sizes of needles in dial are the same as syringe. The second one is needles larger than syringe, and the third one is needles smaller than syringe. The third one is better. Because interlock machine is commonly delayed timing. Needles on syringe hook yarns into loops. When syringe falls with yarns, needles on syringe feed yarn to needles on yarn. Based on the methods used by interlock machine, taking-up or pulling load on syringe is larger than dial. Different sizes of needles can make positive and negative loops equal. So, choosing dial and syringe and sizes of needles play a key role. Wrong choosing must cause difference between positive and negative loops and make quality of clothes fall.

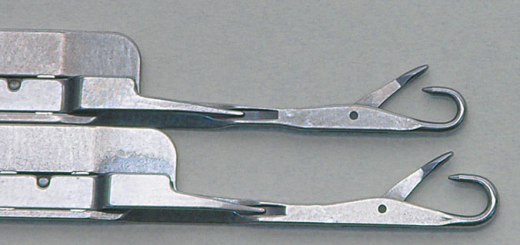

Types of pinhooks

Pinhooks are classified into R type and P type. The former is ordinary type and the later is gasket type also called as robot head needles. This type can make position of two yarns change uneasily during knitting to realize good covering.

Thickness of needles

Thickness of needles is cross sectional dimensions of needles. In terms of single jersey machine, cross sectional dimension of needles on 12~18 needles/24.5 is 0.54mm; 20~24 needles/25.4mm is 0.52mm; 26~30 needles/25.4mm is 0.41mm; 32~40 needles/25.4mm is 0.36mm. However, nonstandard syringes are used to cooperate with special varieties. New needle Litespeed used for high-speed circular knitting machine by Groz-Beckert is common use in market. Part of surface on body has been polished to reduce friction between needles and syringes and improve lubrication, reducing heat under high speed operation. But, in application, the needle cannot be used with old type. It is found that needles bend or deform during insertion and extraction.

2.Relationship between triangle and knitting craft

Materials of triangle

According to Japanese standards, materials commonly used for triangle are SKD11 (Cr12MoV in China), a kind of alloy steel. Hardness of triangle ranges from 62 HRC to 64 HRC, which is higher than needles by 5 HRC. Needles range from 55 HRC to 58 HRC. The other materials are SKD 12, which are used for triangle suffering from high stress or impact.

Design of curved cam

In general, triangle passageway is larger than needle butt by 0.2mm. In terms of looping, triangle have cast on, elevating and pressing. During cast on and elevating, the knitting angle increases, reducing the number of needles in knocking over and forming low tension. During pressing, knitting angle increasing also can reduce needles in kinking and lateral dimension of triangle meanwhile, which is helpful for increasing numbers of incoming line. However, angle of triangle cannot increase without limitation. Overlarge angle can cause priming wire, high load on machine and mingle needle butt. So, theoretical value is lower than 57°. The angle is closed with diameter and channels on machine.

3.Triangle cure

In the early time, due to lack of frequency converter, trigonometric curve on some machines is multiple equation curve. The curve can cause smooth transition for needles moving on surface and improving revolving speed a lot. But, currently, triangle on most of knitting machines adopts arc and straight line. In the position which arc intersects with straight line, accelerated velocity still has saltation. Soft impact exists between needles and triangle, which is also one of main reasons limiting revolving speed of knitting machines.