People have learned about the message that makes knitting shirts by using 3D printing. In theory, using 3D printing can make wearable and comfortable clothes. So for, comfort clothes made out by 3D printing is still far from ideal. Some clothes made by 3D printing are considered as armor in Middle Ages instead of clothe.

However, a program – Technical Crafting in UK may push 3D printing forward. The program is carried out together by Mark Beecroft and Laura McPherson, two researchers from Manchester College of Art and Technology. They try to combine digital technique with theories and practical knowledge of textile.

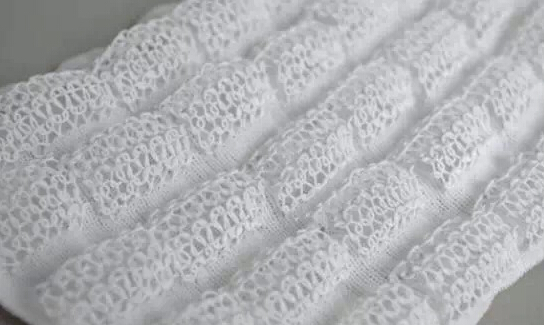

They began the research about 6 months ago. Currently, they have already achieved some interesting achievements. Their direct goal is to use 3D printing to develop a series of soft textile samples. Ideally, those textile samples manufactured by 3D printing can be used for wearable and soft fabrics in the future. Although the effects still cannot be seen, Mark ensures that softness and fineness of samples can compare favorable with real clothes.

They concentrate on how to use 3D printing to represent conventional mode of production which means that shapes of fabrics and interlocking picture which only can be seen under microscope are their starting point.

Two researchers decide to keep the weave structure of clothes made by 3D printing. The structural features can combine new technology with old technology effectively. They hope that 3D printing can become a part of completely integrated, functional fabrics manufacturing system. Nowadays, they are also exploring dyeing, heat setting and processing capacity of nylon materials made by 3D printing.