Circular knitting yarn for mainly by institutions, weaving agencies, pulling up mechanism, transmission, lubrication cleaning mechanism, electrical control mechanism, frame parts and other auxiliary means.

1. Yarn feeding mechanism

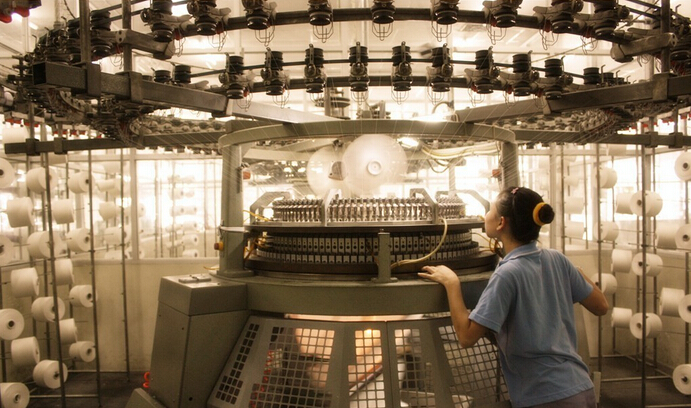

Yarn yarn feed mechanism, also known institutions, including Creel, lose yarn, yarn guide, yarn lap tray. Among them, lose the thread now recognized as the industry’s best aspect is that the United States and Germany Minge · Eero’s products (Figure 1).

To require yarn agencies:

1.1 yarn agencies must ensure uniformity into the yarn tension and continuous quantity and so woven fabric consistent size and shape of the coil, resulting in smooth and beautiful knitted fabric.

1.2 yarn into yarn reasonable mechanism to maintain tension, allowing the fabric to reduce leakage needle, weaving defects decreases.

Yarn than knitting between 1.3 each system must be consistent. The yarn should be able to adjust the amount to suit the needs of transformation products.

1.4 To lose yarn yarn neatly tension more evenly and effectively prevent yarn breakage.

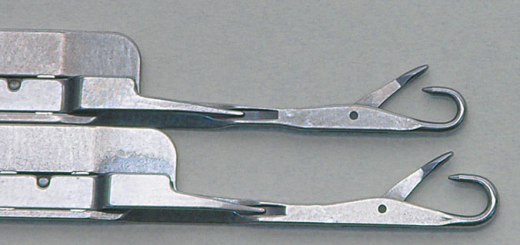

2. knit organization

Circular knitting knit organization is in the heart, mainly by syringes, needles, Triangle, Triangle (including needles and sinkers Triangle and Triangle), sinkers (commonly known as the Sinclair tablets, Sinker) and so on.

3. pull up mechanism

Pulling the winding mechanism of action is to draw the knitted fabric knitting area from out and wound into a certain package form. Including pulling rolls, cloth roll, Spreading frame (also known as support cloth), a drive arm, adjustable gearbox. Its characteristics are:

3.1 At the bottom of the market is equipped with sensor switch, when a cylinder fitted with a drive nails through the arm, will produce a signal for measuring the volume number and the number of revolutions of the cloth.

3.2 in the control panel to set the number of revolutions per operation bolts of cloth, when the number of revolutions of the machine reaches the set value, it will automatically stop, in order to control the weight of the cloth after each match error is within 0.5 kg, the beneficial dyed with vat .

3.3 Takedown rack set number of revolutions can be subdivided into 120 sections or 176 segments to adjust, to large-scale, accurate to adapt the volume requirements of various knitted fabrics.

4. transmission

By inverter control continuously variable motor (motor), then the motor drives the drive shaft gear, passing gear to market, thus boosting the syringe operation. Drive shaft straight to the top knitting machine, and then drive the yarn feed mechanism.

5. Lubrication cleaning mechanism

Circular knitting machine is a high-speed operation, co-ordination of sophisticated systems, since the yarn in weaving process will cause a lot of fly (lint), the central part of the completion of the knitting is easy because fly, dust and grease caused by movement of the poor, serious when will damage the equipment, so lubricate moving parts, dust is very important. Currently knitting machine lubrication dust injector system, radar fan, oil accessories, oil spills and other parts of the slot.

Features lubrication cleaning mechanism is:

a. woven surface of the part dedicated to provide good lubrication oil mist injector machine for, oil and fuel intuitive visible indication when the shortage of oil in the injection machine, it will automatically shut down warning.

b. The new electronic automatic refueling the setting, the operation more convenient and intuitive.

c. radar fan clean wide, woven from yarn accumulator to remove part of a wide range of fly, fly to avoid tangles resulting in poor supply of yarn.

6. control mechanism

Control mechanism used to complete the set of operating parameters, simple button operation, automatic stop and fault indication. Including inverter, control panel (also known as operating board), electrical control box, fault detection equipment, electrical wiring.

7. frame parts

Rack section includes three foot (also known as offal), straight leg (also known as the feet), the market, trigeminal, protective door, Creel seat. Requirements rack section must secure, safe.