the principle of shifting rib circle knitting machine

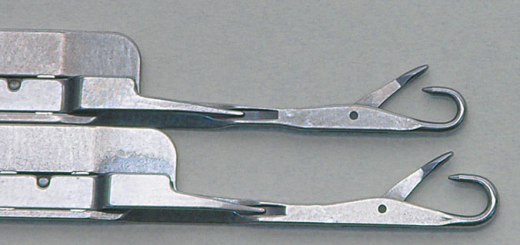

On the shifting rib circle machine knitting circle shift organization, the first coil should move the needle on the dial. Needle grooves in the cylinder, the expansion ring is inserted with the latch needle plate, expanding ring of spring steel sheet is bent, one end of which is secured to the needle bar, and the other end close to the knitting needle bar groove, and the other there incision (also known piece shoulder) on expanding circle piece.

Move ring installed on the machine has a triangular base and rib needle selection mechanism used exclusively for moving coil (flower disc, put chip, inserts, roller, etc.), the need to move the needle circle rises above the ring back location. At this point, expanding circle piece penetrates the coil, the coil expansion, and resting on the incision, followed by the needles on the disc outwardly (dial needles can rise to the position of the needle is not unseating ), through the needle bar and the diffuser ring is composed of sheet voids and move the dial needles, the cylinder coil is hooked on the knitting needles. With the decline of syringe needles, between the coil from the syringe needle knitting circle piece rod and extend the gap at the slide. When the syringe needle continues to drop, the stitches from the needles of the cylinder needles and take off, and transferred to the needles on the needle plate at this time, the needle of the needle is no coil. When the needle reaches the next before a loop system (ones), when the syringe needles rise, by means of the tongue opener (also known as the open needle), the needle off the tongue (that is, the coil is removed syringes the needles of the tongue) is open, ready to weave.

Using shifting circle weave rib-knit organization called the shifting circle, also known as leno. It is based on the basic organization of the weft, according to the pattern required to shift some of the ring coil, the coil that is transferred from one to another wale wale formed. Because of the way the law shifting circle varies, the use of different types of organization (flat needles, interlock, rib tissue) and shifting circle way, you can form a variety of patterns effects (patterns) in the knitted fabric surface.

the shift points rib machine debugging circle

1 shift in the security circle rib machine maintenance, hedge cloth (also known as the hanging fabric, buckle cloth), you need to dial cloth cover on the needle, which is different from other knitting machine. The reason is that the syringe with the needle incision easily hooked cited cloth, not easy unseating.

2 Oil is not too tight, put the appropriate length of the coil length. The main reason is to be transferred into the coil elastic expansion ring films, needle loop is rapidly expanding, causing tension mutations.

3 coiling tension can not be too large, otherwise prone to holes. In order to ensure the smooth progress of weaving, coiling tension adjustment should be slightly smaller than the other product specifications.

4 take lag (after eating, asynchronous) into a circle, and note the dial needles pressure needle not too deep, or prone to holes.

5 weaving a yarn tension control in general 4.9 ~ 7.84 cN (5 ~ 8 g) is appropriate. Too prone to holes, too small needle prone to leakage.