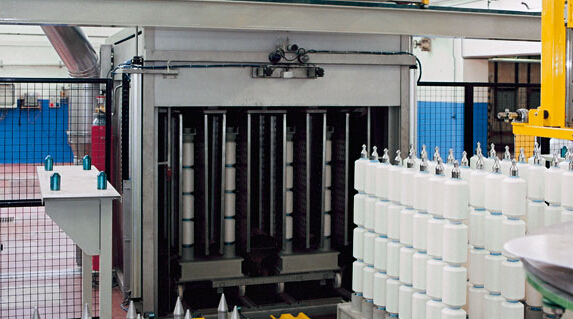

Drying is an essential step for yarn dyeing. About 60-80% water was dried by dryer. After Hydro, double jersey knitting fabrics enter into drying section. The following are the two types of yarn dryers widely utilized in yarn dyeing industry:Stray-field FASTRAN Machine, GALVANIN (Hot Air Dryer)

Mechanism of yarn dryers: There various types of yarn dryers being widely utilized in yarn dyeing industry.

Direct method of heating also called as dielectric heating is the method that where the heat is generated within the materials itself with ratio frequency and microwave method.

Most of temperature of most non-metallic substances will rise uniformly when the substances subjected to a high frequency electric magnetic field. With reversing the direction of the applied RF field, the polarization of the individual molecules within the substance changes. Friction leading to a rise in temperature in turn is caused by the constant molecular movement. The higher the frequency of the electromagnetic field is, the faster the molecules process, then creating more friction and more heat being produced.

The frequency of the RF fields generated by devices for dielectric heating ranges from 13.50MHZ and 27.12 MHZ.

Stray-field FASTRAN Textile Dryer.

Brand Name: Stray-field

Country Origin: UK

Supply Voltage: 380-420

Supply Frequency: 50 HZ

Supply Phases: 3

Supply KVA: 230

Supply Power Factor: 0.9

Maximum Weight: 3800 Kg

RF Power Output: 100 kW

Operating Frequency: 27 MHZ

The following tips need to be considered during yarn drying.

Machine Speed: Machine changes its speed based on the shade of the double jersey knitting fabrics. Conveyor runs at a high speed for dark shade while low speed for light shade.

Feeding System: Plastic package feed vertically while spring package feed horizontally because fire can be formed by feeding in vertical form.

Yarn Type: Yarns having same types should run at the same settings. Or else, the quality of yarns may be damaged. Cotton, polyester, acrylic, P/C or CVC yarn should feed separately.

Moisture: Machine settings should follow the amount of moisture remaining in the package.

Evaluation of Efficiency of Dryer: The efficiency of a yarn dryer should be known.

Weight of double yarn package before dyeing=1.2 Kg

Weight of double yarn package with water before Dryer=2.034 Kg

Weight of water in double yarn package before Dryer = (2.034–1.2) Kg =0.834 Kg

Weight of package after Dryer=1.2 Kg

Water remain in package after Dryer= (1.2 – 1.2) Kg =0 Kg

Water removed by Dryer= (0.834 – 0) Kg = 0.834kg

Efficiency={(Weight of water before Dryer-Water remain after Dryer) / Weight of water before Dryer}×100%={(0.834 – 0) / 0.834} X 100%=1×100%=100 %

Efficiency of Dryer = 100 %