Hydro extractor plays an important role after dyeing. Hydro extractors being used for package yarn and fabric differ from each other.

It is necessary to remove excess water from the package by using hydro-extractor. About 60-70% water is dried by hydro-extractor. Package enters into hydro-extractor after dyeing.

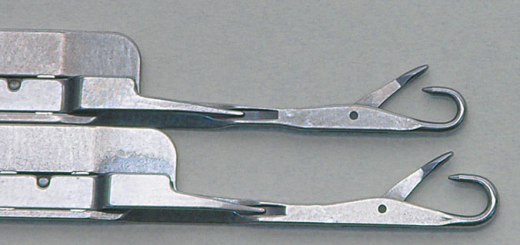

Working mechanism of hydro-extractor: Dyed yarn package is placed on spindle and it enters into basket consisting of a central spindle where the head of the arm is placed. The wall of basket is perforated. The basket rotates at a high revolving speed of 1500 rpm causing centrifugal force which removes excess water. More than 70% of water is removed by hydro-extractor. Then yarn is transferred into dryer.

Evaluation of efficiency of hydro-extractor: The efficiency of hydro-extractor determines the working power of hydro-extractor. The following processes are the evaluation of efficiency of hydro-extractor.

Weight of double yarn package before dyeing =1.2 Kg

Weight of double yarn package with water before Hydro=3.49 Kg

Weight of water in double yarn package before Hydro = (3.49 – 1.2) Kg=2.29 Kg

Weight of package after Hydro=2.034 Kg

Water remain in package after Hydro=(2.034 – 1.2) Kg =0.834 Kg

Water remove by Hydro-Extractor= (2.29 – 0.834) Kg =1.456 kg

Efficiency= {(Weight of water before Hydro – Water remain after Hydro) – Weight of water before Hydro} X 100%= {(2.29 – 0.834) – 2.29} X 100%= 0.63 X 100%= 63%

Efficiency of Hydro-Extractor = 63%

After hydro-extractor, yarn packages are sent to dryer for removing residual water.