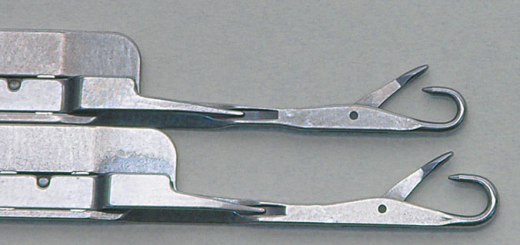

Can is one of core components in circular knitting machine, which is mainly used for controlling movement and forms of motion of needles and sinkers. Cam is generally classified into looping cam, tucking cam, floating cam and sinking cam.

The quality of cam has great influence on circular knitting machine and knitted fabrics. Nevertheless, the following notes should be focused when choosing cam.

Firstly, trigonometric curve should correspond to different requirements of knitted fabrics. For designers having different pursuit for styles of knitted fabrics and different emphasizes, trigonometric also differs.

Secondly, due to needles (or sinkers) slip friction with cam at a high speed for a long time, some process point should also suffer from high frequent impact. So the materials and heat treatment of cam are quite important. GB Cr12MoV is used as raw materials of cam. The material has good hardenability, low quenching distortion. Hardness, strength and tenacity meet the requirements of cam after quenching. Quenching hardness of cam is general HRC63.5±1. Overhigh or overlow hardness can result adverse effects.

Lastly, roughness of cam has high importance. It has direct influence on usability and wearing resistance of cam. Roughness is decided by processing equipments, tools, processing technologies, cutting and other factors. Roughness (Ra) is usually lower than 0.8 μm. Poor roughness may result in needle butt wearing, needles hitting and cam seat overheating.