Day Maintenance of Circular Knitting Machine

a. morning, noon, night three shifts, must remove attached to the fiber creel and machinery (fly), kept clean and stretch knit unit winding mechanism.

b. shift when actively feeding devices to check, to avoid clogging by fly yarn storage, rotation is not flexible, causing the surface of the fabric Dahenglu other defects.

c. each class will check automatic stop device and safety gear shields, if unusual, immediately repair or replacement.

d. the shift or tour inspection, you must check whether the oil market as well as throughout the flow.

Week Maintenance of Circular Knitting Machine

a. doing cleaning work yarn feeding speed disk, the inner disk accumulated fly cleaned.

b. Check transmission belt tension is normal and drive smoothly.

c. carefully check the functioning of the traction winding mechanism.

Month Maintenance of Circular Knitting Machine

a. remove the triangular seat, remove accumulated fly.

b. Check the wind and dust removal device are correct and clear above the dust.

c. clear fly within electrical accessories, electrical accessories repeatedly check the properties, such as self-stop systems, security systems and so on.

Half Maintenance of Circular Knitting Machine

a. put all circular knitting needles and sinkers disassembled, thoroughly cleaned, and check there is no damage, if there is damage, immediately replaced.

b. Check all the oil is smooth and clean injection equipment.

c. Clean and inspect the positive-type yarn feed mechanism is flexible.

d. fly with grease to clean the electrical system and its maintenance.

e. Check the oil waste oil collection is smooth.

Knit circular knitting machine maintenance organizations

Weaving mechanism is the heart of knitting machine, which directly affect the quality of the product, and therefore is essential for the maintenance knit organization.

a. knitting machine in the normal operation period (the length of time depending on the quality of equipment, woven material may be), the needle groove needs to be cleaned to prevent contamination knitted into the fabric as woven, but also can reduce the circuit thin needle defects (also known as needle) appear.

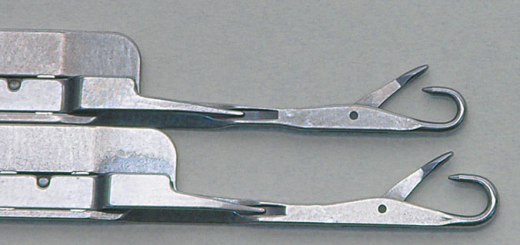

b. Check all needles and sinkers for damage, if damaged, must be replaced immediately, if used for too long, affecting the quality of the fabric, you need to consider replacing all of the needles and sinkers.

c. Check the needle plate and the syringe needle groove wall damage, if problems are detected, immediate repair or replacement.

d. Check for wear triangle and confirm that it is installed properly, the screws are tightened.

e. Check and correct installation location yarn feeding mouth, if found badly worn, you need to be replaced immediately

Circular knitting machine lubrication

a. Check the oil level mirror the market every day, if the oil level is below the two-thirds mark, you need to refuel. When half the maintenance, if found oil in sediments, then all should be replaced with new oil.

b. If the transmission gear is oil-like stains, to increase once the oil in 180 days (6 months) or so; If grease lubrication, need about 15 to 30 days plus a grease.

c. months at the time of maintenance, lubrication checks throughout the drive bearing grease.

d. All components must use unleaded knitting knitting oil, day shift staff responsible for refueling.