Striker means circular knitting needles in the device during operation, due to collision, causing the butt of the needle bar or break phenomenon case more generally broken butt. Frequently occurs while the machine is running is not normal needle butt, once this phenomenon, first look at whether the needle butt of the knitting needle on the needle position and the needle butt retained more above or below the more (less side of the striker position) to determine which parts of the triangular needle is in the off. If the needle is not out of the cylinder port, described in connection triangle off. There remain in the firing pin when the needle bar up and down the butt of the residue is not as much as if the needle butt of the needle to stay below the butt rod is less, indicating the position of the striker pin in the lower track, the contrary is breakage caused by the above.

Striker means circular knitting needles in the device during operation, due to collision, causing the butt of the needle bar or break phenomenon case more generally broken butt. Frequently occurs while the machine is running is not normal needle butt, once this phenomenon, first look at whether the needle butt of the knitting needle on the needle position and the needle butt retained more above or below the more (less side of the striker position) to determine which parts of the triangular needle is in the off. If the needle is not out of the cylinder port, described in connection triangle off. There remain in the firing pin when the needle bar up and down the butt of the residue is not as much as if the needle butt of the needle to stay below the butt rod is less, indicating the position of the striker pin in the lower track, the contrary is breakage caused by the above.

1.Triangle problem

1.1 Triangle imported surface without chamfer or chamfer too.

Triangle imported surface without chamfering, tactless, leading to the firing pin. Chamfer is too big, butt directly into the triangle by the chamfer line, can easily lead to the firing pin.

1.2 Triangle bevel angle is too

Increasing slope angle triangle, in the course of operation of the machine receive the butt of the cylinder tangential direction of the force increase, so prone to the striker, the needle butt breakage. Only in this case the plane grinding triangle appears, the smaller the diameter of the barrel, the less large ones, triangle wider, more prone to this problem, the circular grinding or bending process technology triangle triangle no such problems.

1.3 is too large a gap between the triangular

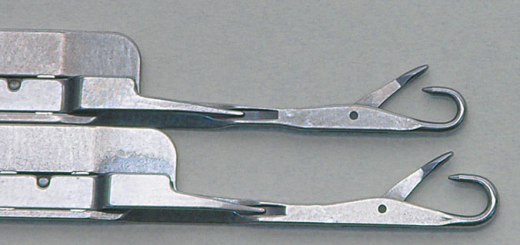

If the gap is too large triangle between the needles in the triangle between the two when running to get stuck into the gap between the triangle, resulting in the firing pin. Backlash theory, triangle and a triangle between the needles can not be greater than the thickness of the brand now has high-end knitting needles can be done about the thickness of the thinnest 0.26mm. So the gap between the triangle and the triangle should ensure between 0.10 ~ 0.20mm.

1.4 triangular surface irregularities

Triangle by the prolonged friction, resulting in uneven surface, it is easy to striker.

1.5 Triangle needle tract problems

The triangular heel needle tract breakage and clean or untreated narrow needle tract problems also occur striker.

1.6 Improperly installed or Triangle Triangle Block

When replacing screws triangle triangle triangle above the surface, the screws are not tightened good cause triangle or triangular flat seat is not installed, may cause the firing pin. In addition, the size of the error triangle base size of the error, or install triangular column, when the seat is installed below the triangle dirty, causing the gap error device and syringe each triangle between more than 0.05mm, also a striker. Because After installing this triangle or triangular seat to carefully check

1.7 Triangle inappropriate material or heat treatment of steel to soft

The impact of intolerance triangular steel to soft materials caused, do not wear, heat treatment caused triangle triangle deformation and brittle fracture, are also the cause of the firing pin.

1.8 flat triangular needle is not perpendicular Road and Triangle

Normal triangular pin needle tract to go with the triangle plane is perpendicular to the plane. Sometimes when milling triangular needle tract, milling and processing surface is not 90 °, so that would make the triangular needles knitting needles and needle tract contacts go bad when the needle, resulting in the firing pin heel phenomenon.

2 needle groove reasons

2.1 needles in needle groove with too loose

After knitting needles or needle groove wear, knitting needles when the needle groove running around shaking exacerbate easy firing pin; the need to use some special fabric and thin needles into the syringe model coarse weave, easy firing pin.

2.2 needle groove tight

Knitting needles needle groove tight lead up and down or back and forth motion can not follow the trajectory of needle tract, causing the firing pin.

2.3 needle groove groove depth is too shallow

Needle groove deep enough or dirt accumulation caused by the needle body exposed on the outside of the needle groove will cause the firing pin, the general body of the needles should be below the surface of the needle groove around 0.05mm.

3 other reasons

3.1 needles quality problems

If the quality is not up to the needles, the intensity is too low, under normal production conditions may also occur striker.

3.2 needles and needle tract in oil

Lack of oil lubrication can cause the needle and the needle groove surface to reduce surface friction coefficient increases, the needle butt force increase, easy firing pin, so to conduct regular maintenance and inspection of equipment to prevent starvation conditions.

3.3 needle moisture in oil

Needle oil contains mostly similar surfactant component, water intrusion needle oil, oil will reduce the lubricity of the needle, the needle can cause the deterioration of the oil. Inferior needle oil or improper needle oil viscosity will reduce lubrication, causing the firing pin.

3.4 Gap syringe (disk) and between the large triangle

Gap syringe (disk) and triangle between too large, causing the needle through certain triangle, the triangle butt can not run along the runway, so the needle will run to the other triangle when striker occur. General syringe (plate) and the gap between the triangle was (0.2 ± 0.05) mm, some models may be smaller clearance requirements.

3.5 hook or fly in a lot of chaos yarn feeding

Sided machine during operation, if the hook while feeding a large fly or chaos yarn, knitted hinder pressure needle drops, causing butt break.

3.6 dial position beating too large

Causing the needle plate position beating too large for two main reasons, one is the device itself unstable; Second, horizontal or concentric needle plate no debugging within the standard range.

3.7 Equipment transmission gear gap is too large or one-way bearing damage

Sharp or emergency stop devices of the moment, because of inertia, syringes have extended run in the opposite direction of the trend. With different knitting machine, circular curve design triangle reciprocating machines can not operate if the device drive gear gap is too large, the other knitting machine are generally equipped with one-way bearing, one-way bearings can also cause damage to machine downtime when the syringe instantaneous reverse rotation, so that the striker occur. In addition, because Tenders under the cloth, the cloth roll force needed to pull down the lever in the opposite direction round machine operation, if the gap is too large transmission gear device, the machine can also cause the firing pin.

3.8 appropriate adjustments Winding Machine

Some of the machines are old, this machine has all aspects of the above problems, conditioners while weaving in ensuring normal prerequisite to relax as much as possible rolling machine volume Brad force, to reduce the force of knitting needles, and vice versa will produce striker.