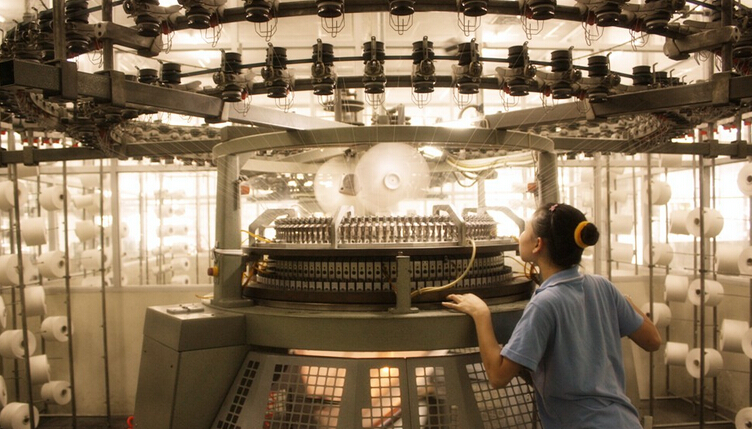

A drop of water dripping needle plate holder, this phenomenon exists in the duplex circular machine, because the machine during operation will generate a lot of heat, especially in the syringe, the triangular part of the temperature becomes very high in the air in this section will be heated, moisture in the air into a gaseous steam, and rapid increase when the vapor leaving the needle plate, the syringe into the center of the high temperature region of the sleeve portion, with the lower ambient temperature, water vapor condenses into water droplets and re-attached on parts, the accumulation of the future will be more along parts shed into bead plate, tripod and other parts.

Solution:

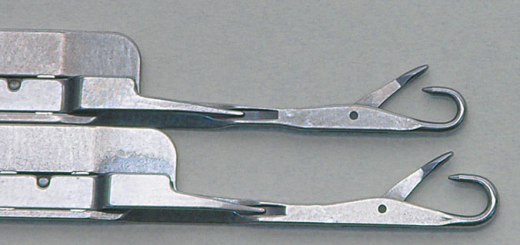

The solution is to cut off the air rising channel, good seal, the center of the central sleeve threaded holes (mounting holes middle hair tube) at doing sealed, large tripod should try to seal the edges of the lid to prevent large tripod at water. Further, the gap between the dial cam holder not too much, with the needle plate Bead gap between the disc, the gap between the needle plate and the cam do not too large to prevent the flow of air, thereby preventing the water produced at the disc Bead .

Of course, when the workshop ambient temperature is high, humidity, condensation phenomenon is inevitable, but mostly outside of the machine condensate, few internal condensate phenomenon. But after the air circulation inside the machine up, it will produce a lot of condensation.